Knowledge Base: Turbo vs Rotary Nozzle

Understanding Turbo Nozzles (Rotary Nozzles): A Knowledge Base Guide

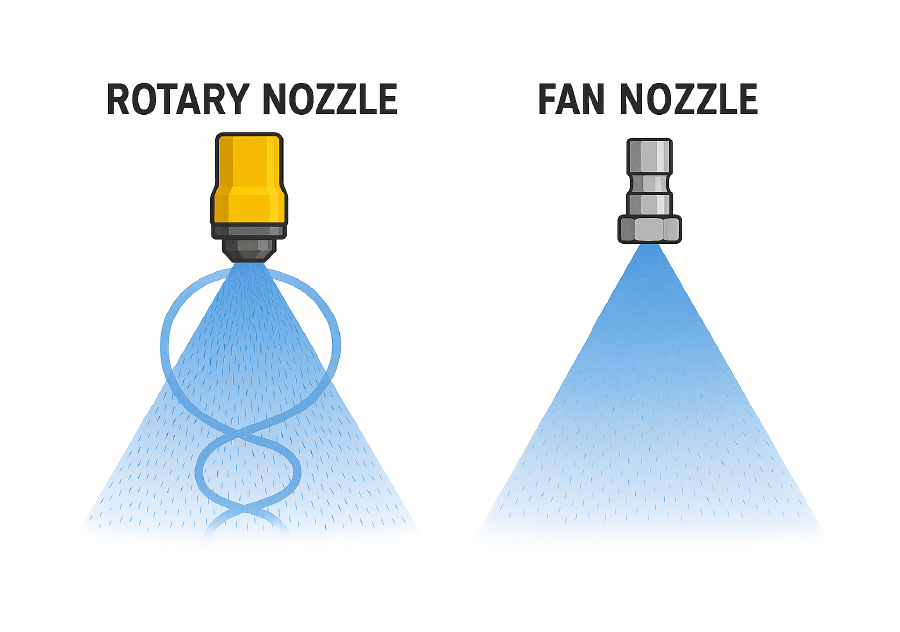

Turbo nozzles, also known as rotary nozzles, are high-performance pressure washer accessories designed to deliver maximum cleaning power with efficient coverage. Their unique internal mechanism transforms a zero-degree jet into a rotating, cone-shaped spray pattern—making them ideal for demanding cleaning tasks.

Why Are They Called Turbo or Rotary Nozzles?

The term “turbo nozzle” comes from the high-speed rotation of the water jet inside the nozzle. This spinning action, powered by water pressure, produces a circular spray pattern that combines the intensity of a zero-degree jet with the coverage of a fan spray—making it ideal for tough cleaning tasks.

The name “rotary nozzle” highlights the internal rotation mechanism, typically driven by a loose ceramic or steel ball (sometimes referred to as a turbine). As high-pressure water flows through, it causes this ball to spin rapidly, creating a rotating jet stream that delivers faster cleaning and deeper penetration into grime, grease, and buildup.

While not a turbine in the traditional mechanical sense (with blades or vanes), this spinning ball functions like a turbine by converting water pressure into rotational motion. It’s the core component that gives turbo nozzles their powerful and efficient cleaning performance.

Best Applications for Turbo Nozzles

Turbo nozzles are best suited for heavy-duty cleaning tasks, including:

- Concrete and brick restoration

- Graffiti and paint removal

- Fleet and construction equipment cleaning

- Agricultural machinery

- Industrial surface prep

- Tank and vessel cleaning (as highlighted by Spraying Systems Co.)

Their ability to deliver high impact force while covering more area makes them a time-saving solution for professionals.

Materials Used in Turbo Nozzles

Turbo nozzles are built from durable, wear-resistant materials to withstand high pressure and abrasive environments:

- Ceramic: Used for internal rotors due to its hardness and longevity.

- Stainless Steel: Offers corrosion resistance and structural integrity.

- Brass: Common in budget models; less durable than stainless steel.

- Polymer Composites: Lightweight and cost-effective for outer housings.

Material selection affects performance, durability, and compatibility with chemicals or harsh environments.

Safety Considerations

Turbo nozzles generate high-impact, concentrated spray patterns that can cause injury or damage if misused. Key safety tips include:

- Never point the nozzle at people or animals.

- Avoid using on delicate surfaces like wood, paint, or soft plastics unless rated safe.

- Wear protective gear—especially gloves and eye protection.

- Start with a test spray on a small area to assess surface tolerance.

- Ensure proper PSI/GPM compatibility to prevent internal damage or dangerous spray behavior.

Environmental Impact

While turbo nozzles are efficient, they also raise concerns about water usage and runoff:

- Water Efficiency: Their faster cleaning action can reduce total water usage compared to fan nozzles.

- Runoff Management: High-pressure cleaning can dislodge contaminants that enter storm drains or soil. Use containment systems or recovery vacuums when cleaning hazardous surfaces.

- Eco-Friendly Practices: Pair turbo nozzles with biodegradable detergents and follow local regulations for wastewater disposal.

Comparison Chart: Turbo vs. Fan vs. Zero-Degree Nozzles

Here’s a quick reference chart comparing three common nozzle types:

| Nozzle Type | Cleaning Power | Coverage Area | Water Efficiency | Surface Safety | Typical Applications |

|---|---|---|---|---|---|

| Turbo Nozzle | High | Medium (Rotating Cone) | High (Fast Cleaning) | Moderate (Can Damage Soft Surfaces) | Concrete, Graffiti Removal, Industrial Equipment |

| Fan Nozzle | Moderate | Wide (Fan Spray) | Moderate | High (Gentle on Surfaces) | General Cleaning, Vehicles, Windows |

| Zero-Degree Nozzle | Very High | Narrow (Pinpoint Jet) | Low (Focused Area) | Low (Risk of Damage) | Rust Removal, Spot Cleaning, Heavy-Duty Tasks |

We can Help

If you're interested in learning more about the lineup of products AR North America offers that are applicable to your cleaning needs, check out our line up here. If you have more questions on need assistance contact us today. Our team is ready to help you find the right solution for your application.