Knowlege Base: Nozzles, How Something So Small Makes Such a Big Difference

September 2, 2024

arnorthamerica

Nozzle Size: The Critical Factor in Pressure Washing Performance

In the realm of pressure washing, the size of your nozzle is a pivotal element that can significantly impact your system’s efficiency. Understanding how to choose and maintain the right nozzle size is essential for achieving optimal results.

Here are four essential points to consider:

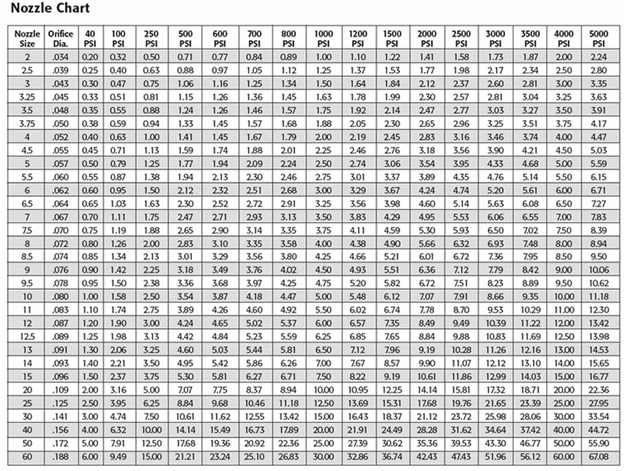

- Proper Sizing with a Nozzle Chart: Utilizing a nozzle sizing chart is crucial for aligning with your system’s specifications. This practice ensures optimal pressure and flow, thereby maximizing cleaning efficiency and prolonging equipment lifespan.

- Understanding a Nozzle Chart: The relationship between flow and pressure through a nozzle follows a root/square principle. Doubling the flow through a nozzle results in quadrupling the pressure, while halving the flow has the opposite effect. Nozzle charts simplify this process by providing expected flows and pressures for specific nozzles. Standard nozzle sizes are designated based on their flow rate (in GPM) at 4000 PSI (e.g., a #4.0 nozzle will produce 4000 PSI with 4 GPM flowing through it). It is imperative to select a nozzle that matches the capabilities of your pump and drive. An oversized nozzle will limit maximum pressure, while an undersized nozzle will waste power, reduce cleaning effectiveness, and potentially cause undue wear to components such as unloaders.

- Properly Sizing Your System to a Nozzle: To properly size your system to a nozzle, follow these steps:

- Determine Your System’s Specifications: Identify the maximum pressure (PSI) and flow rate (GPM) your pump can handle.

- Consult a Nozzle Sizing Chart: Use a nozzle sizing chart to find the nozzle size that matches your system’s specifications. Look for the nozzle that provides the desired pressure and flow rate.

- Match the Nozzle to Your Pump: Ensure the selected nozzle is within the capabilities of your pump and drive. Avoid nozzles that are too large or too small to prevent performance issues.

- Test and Adjust: After selecting the nozzle, test your system to ensure it operates efficiently. Make adjustments as needed to achieve optimal performance.

- Consequences of Improper Sizing: Using an incorrectly sized nozzle can lead to suboptimal performance, including reduced pressure, uneven cleaning, and potential damage to your pump. Ensuring proper sizing mitigates these issues, guaranteeing consistent and reliable results.

- Common Nozzle Issues: Even with the correct size, nozzles are subject to wear and tear. Regular inspections for clogs, wear, and damage are essential to maintain peak performance and avoid costly repairs.

Tips and Best Practices:

- Regularly check your nozzle for signs of wear and tear.

- Use a nozzle sizing chart to ensure you are using the correct size.

- Replace nozzles that show signs of damage or wear to maintain optimal performance.

If you need further insight, we are here to help. email us at info@arnorthamerica.com, or explore helpful formulas here.